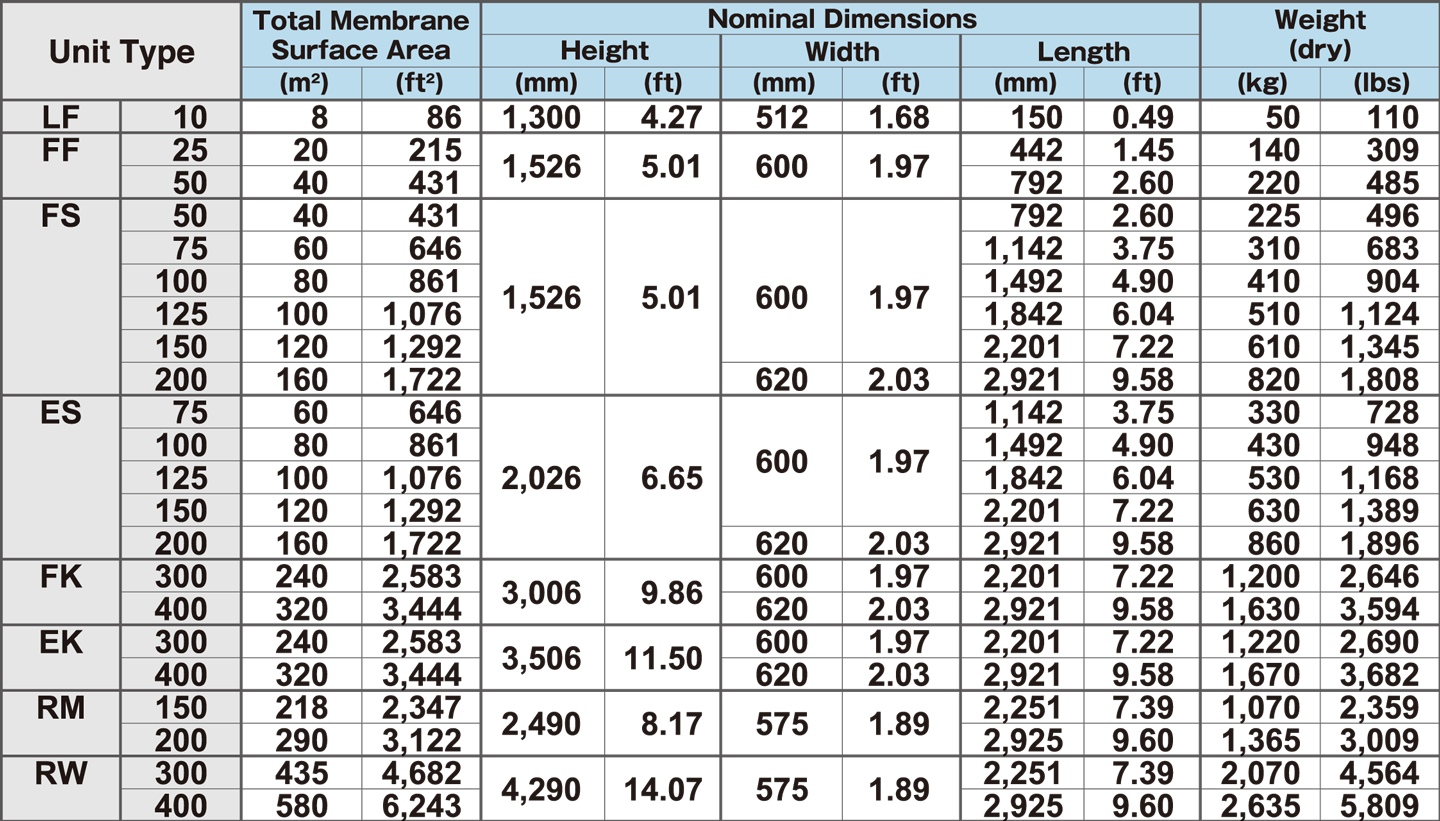

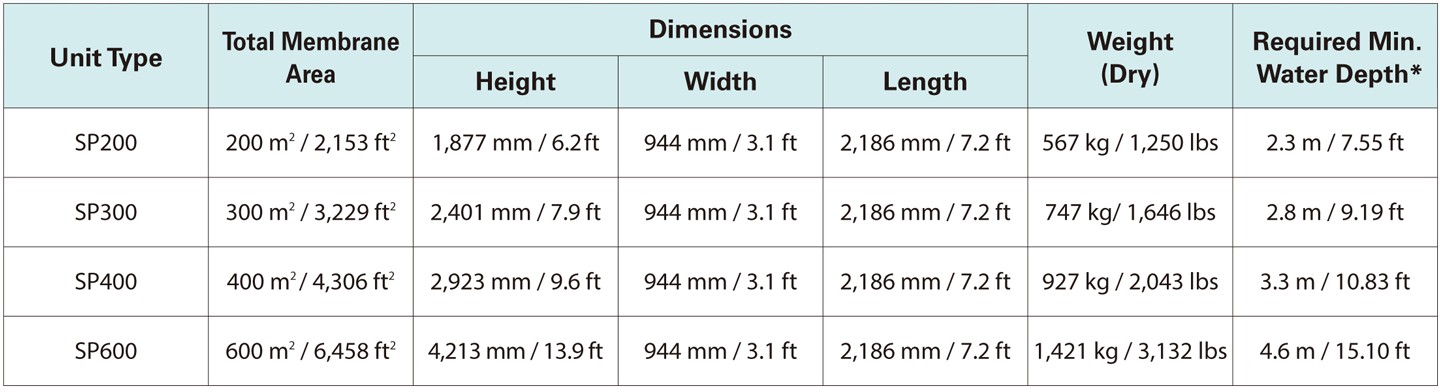

Whether your plant capacity is 20,000 or 20,000,000 gallons per day KWU has the membrane products to fit your facility. Our submerged membrane units (SMUs) are designed specifically to handle the challenging environment of a wastewater treatment facility. From the membrane itself which is designed to allow for the greatest amount of flow while providing the greatest protection from viruses and pathogens to the diffuser under the SMU that keeps the membrane from fouling prematurely while also providing oxygen for treatment, our products represent the best solution for your wastewater needs. Below you can find more detailed information on our different SMU models. Contact us today to learn how KWU has helped owners across the Country meet their permit conditions.

SOLUTION 1:

Non-detect TSS

Our microfiltration membrane provides a positive barrier between the permeate and the mixed liquor allowing our effluent to achieve reuse quality standards.

SOLUTION 2:

Simple Maintenance

Monitor your TMPs and verify appropriate air scour flow rates and you’re good to go. Chemical cleans once every 3 – 4 months are easy to perform and only require a few hours to complete.

SOLUTION 3:

Energy Efficient Operation

By utilizing the air scour to keep the membranes clean and provide oxygen for the treatment process, our membranes get twice the work out of the same energy.

SOLUTION 4:

Smallest treatment footprint available

Our MBRs eliminate the need for clarifier tanks and operate at the highest mixed liquors available in the industry. This means your facility will have the smallest footprint possible and still meet challenging effluent conditions.

To learn about our Ductile Iron Pipe solutions click here.