Membrane Bioreactor (MBR)

What is an MBR? In our opinion it’s one of the most revolutionary technologies the wastewater industry has ever seen. What makes it so special you ask? Do you have tight nutrient limits, click here to see how our MBRs have helped owners achieve TN 3 mg/L or TP .2 mg/L limits. Are you focused on sustainability and the ability to close the circle by turning “wastes” into resources, click here to see how our MBR systems allow water to be cycled and recycled over and over again. Are you a Sovereign Nation needing a wastewater system to support your Tribe’s growth or new gaming operation, click here to see how KUBOTA Water and Environment U.S.A Corporation has helped other Tribe’s cost effectively install and operate systems for their communities. Or maybe you’re a property developer and need a wastewater system that can be hidden in plain sight, click here to see how we have helped other developers install state of the art MBR systems that homeowners aren’t even aware of. No matter what sort of wastewater challenges you’re facing, KUBOTA Water and Environment U.S.A Corporation is here to help you solve them.

See below learn more about the specifics of what a Kubota MBR system is and how it operates.

MBR 101

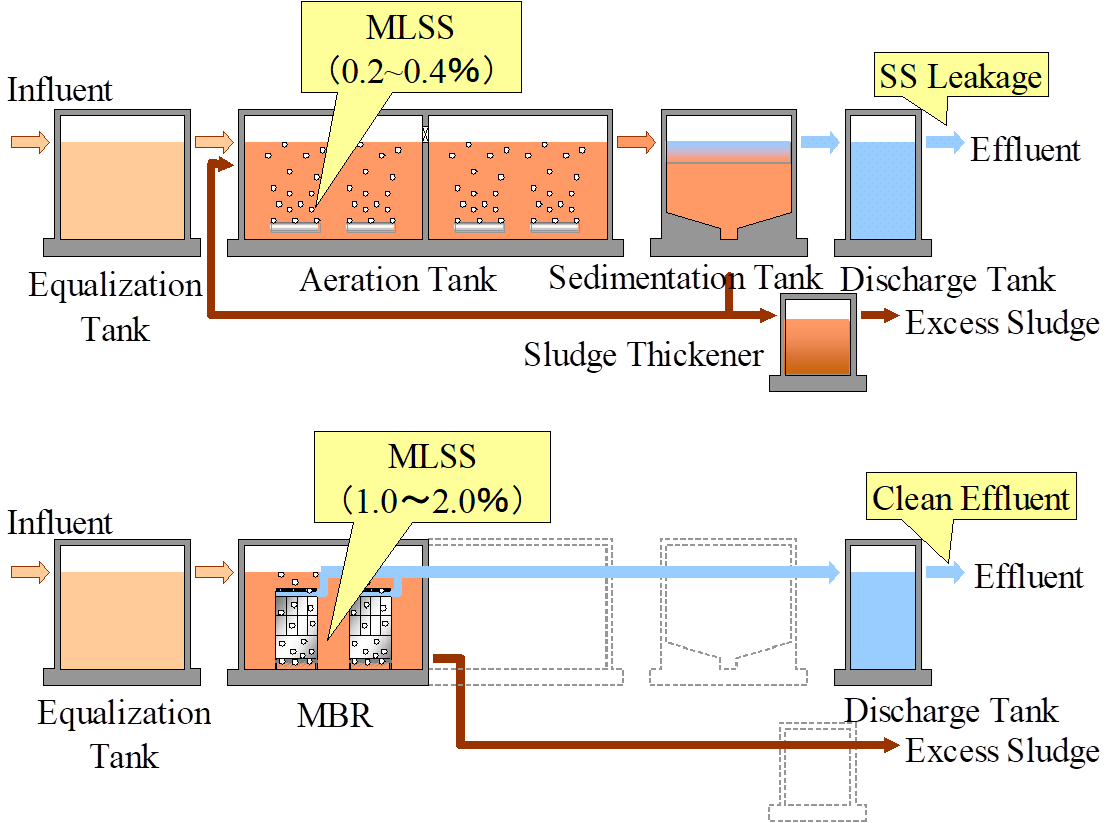

A membrane bioreactor combines conventional activated sludge with micro or ultrafiltration membranes to produce effluent of very high quality. It is different from tertiary filtration in that the membranes reside in the mixed liquor rather than polishing secondary effluent.

This positive barrier between the mixed liquor and the effluent (permeate) leaving an MBR allows an MBR to operate at much higher mixed liquor concentrations than typical conventional activated sludge (CAS). Higher mixed liquors lead to one of MBR technologies biggest advantages; small footprint. Below is a comparison of the unit processes and tanks for a CAS plant vs. an MBR.

Kubota Membranes vs. Hollow Fiber

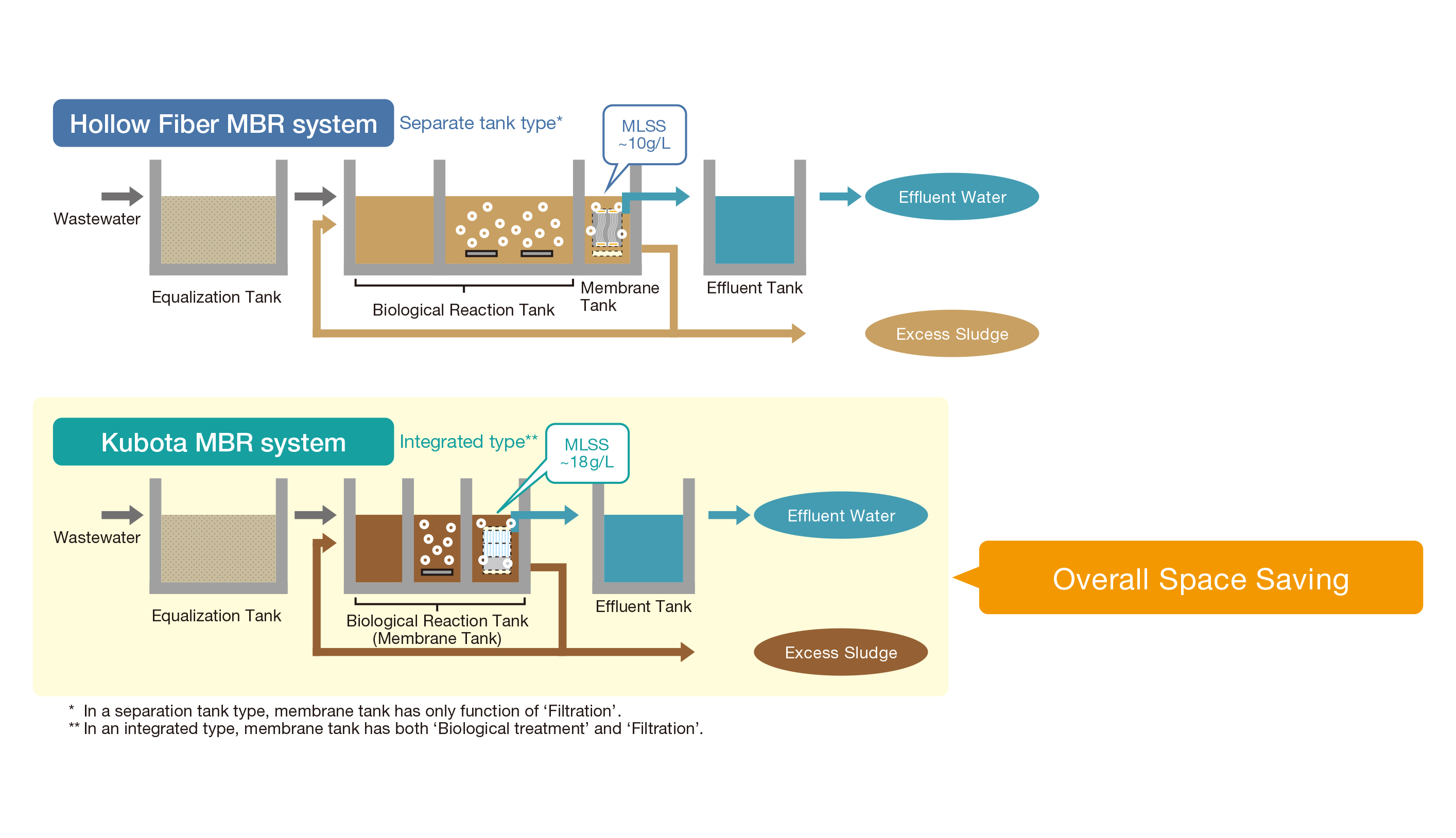

The Kubota flat sheet membrane was developed with one thing in mind; treating wastewater simply and effectively. This focus led Kubota to; adopt a microfiltration (MF) as opposed to Ultrafitlration (UF) membrane, to utilize air scour as the primary means of keeping membranes clean and to build a robust submerged membrane unit (SMU) able to handle the challenging environment of a wastewater treatment facility. All of these factors lead to the advantages a Kubota flat plate membrane offers when compared to hollow fiber.

Kubota learned early in its 40 years of supplying MBR systems that MF membranes provided the greatest throughput with the best effluent quality. Kubota’s MF membranes allow our systems to operate at MLSS concentrations over 15,000 mg/L, which means your system is going to have the smallest footprint possible.

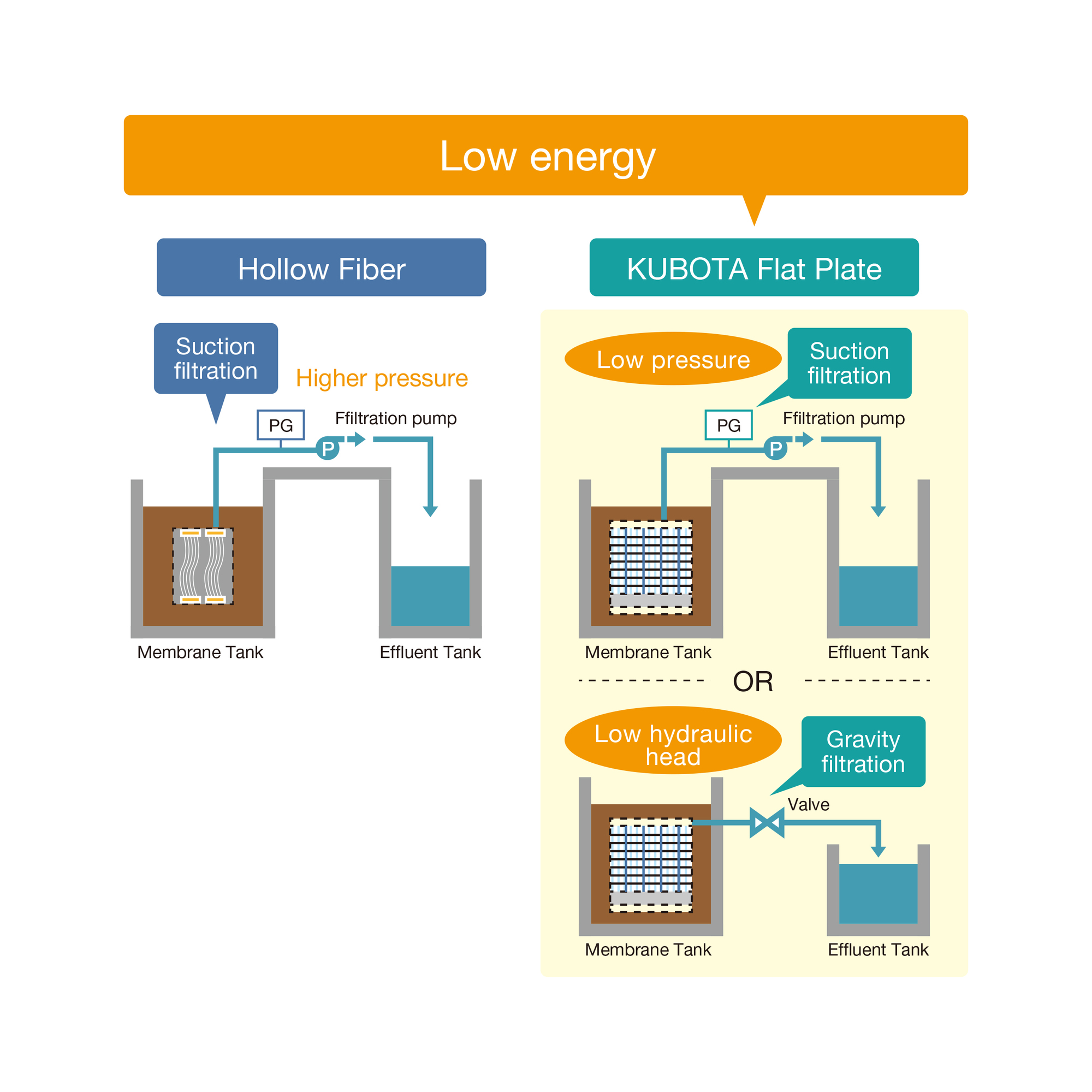

MF membranes also allow our systems to permeate by gravity rather than being pumped. Even if pumping is required due to system hydraulics, our membranes operate at one half the suction pressure of a hollow fiber system. These factors lead to lower energy requirements for your system.

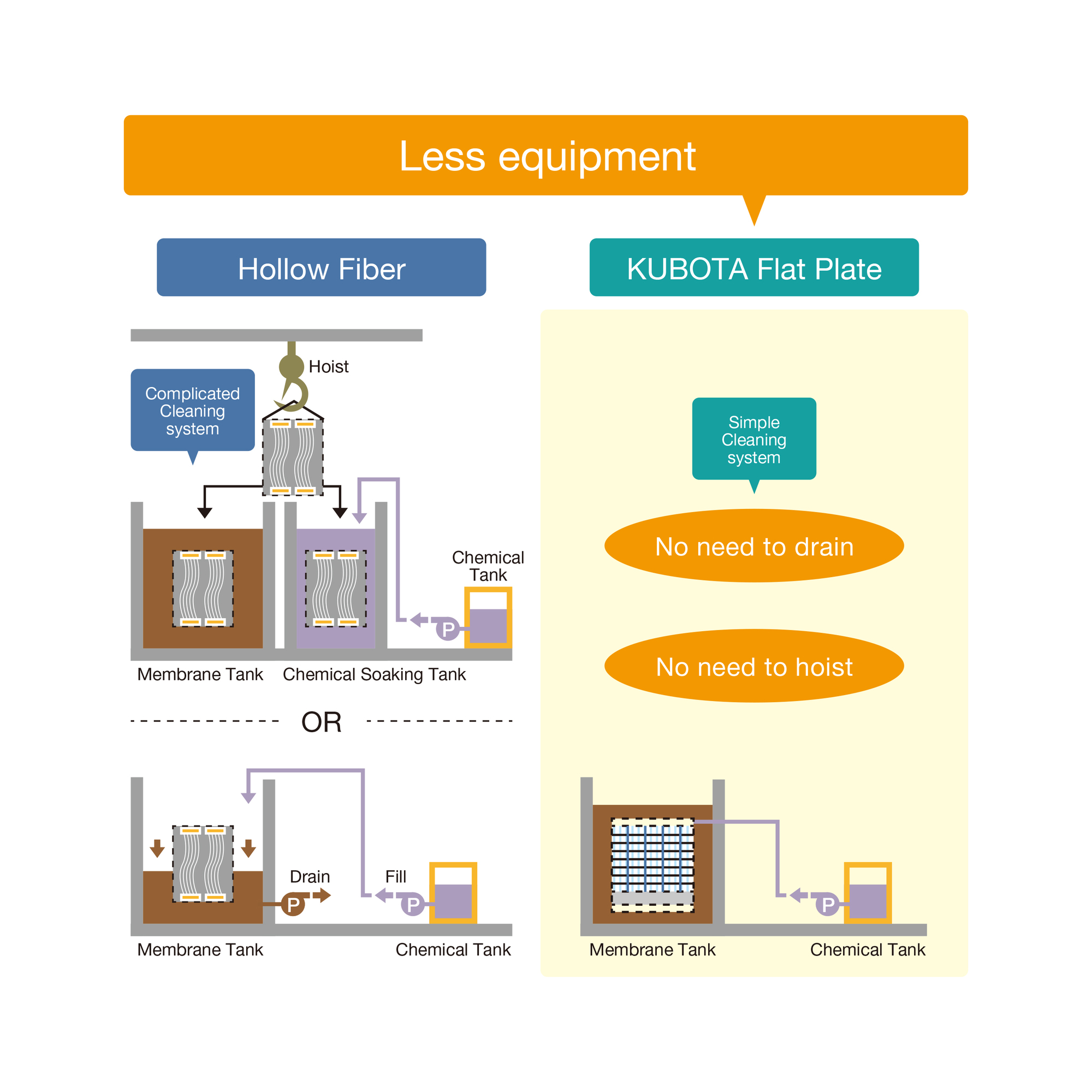

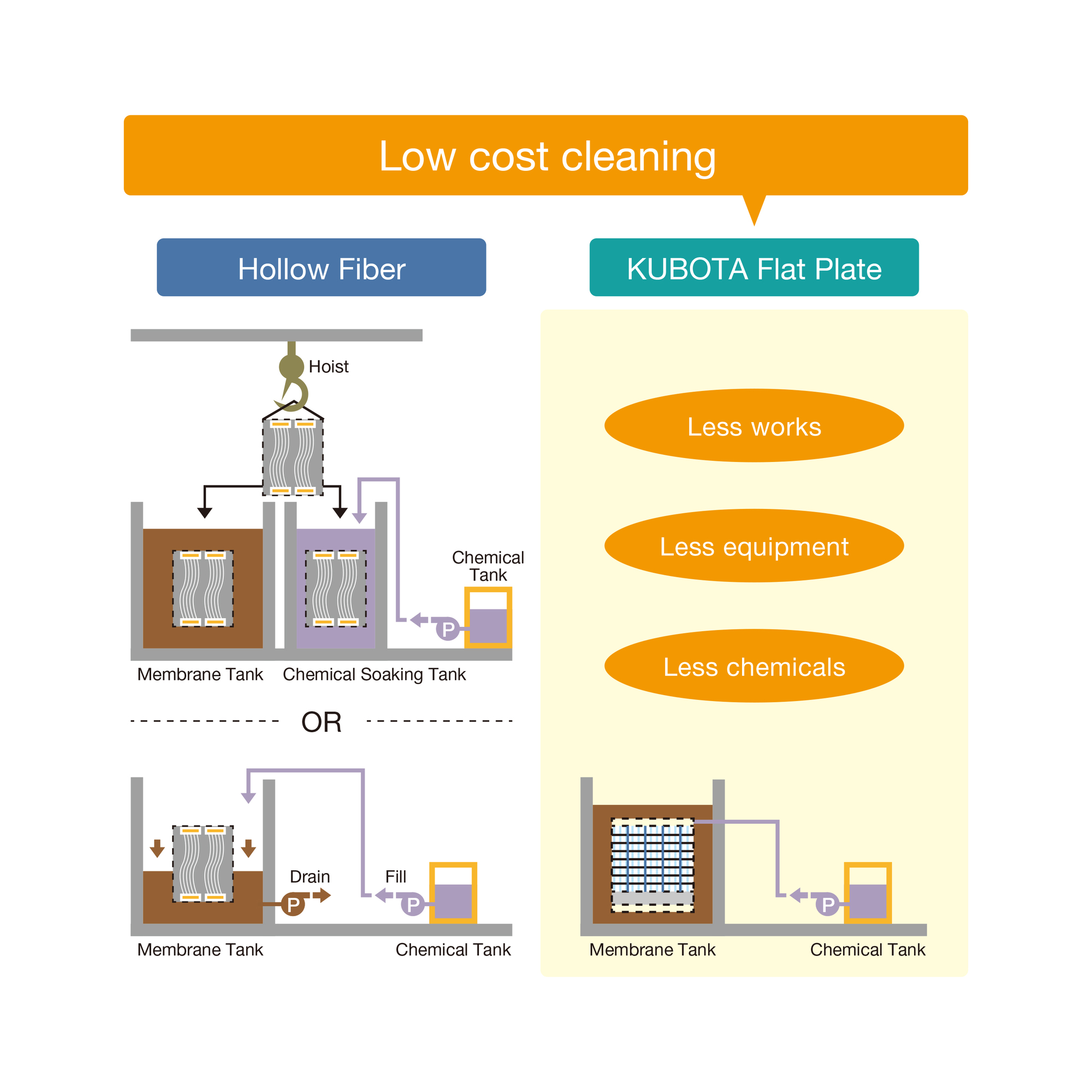

Utilizing air scour as the primary means of cleaning the membranes provides owners with two distinct advantages compared to hollo fiber. First our membranes don’t require a complicated valving arrangement or extra pumps in order to backpulse the membranes, we don’t need it. This reduction in equipment then leads to smaller buildings and lower capital costs for owners.

Secondly our membranes do not need to perform recovery cleans or separate dip tanks for cleaning the way a hollow fiber system would. This advantage leads to lower operating expenses for our owners due to lower chemical consumption and labor costs.

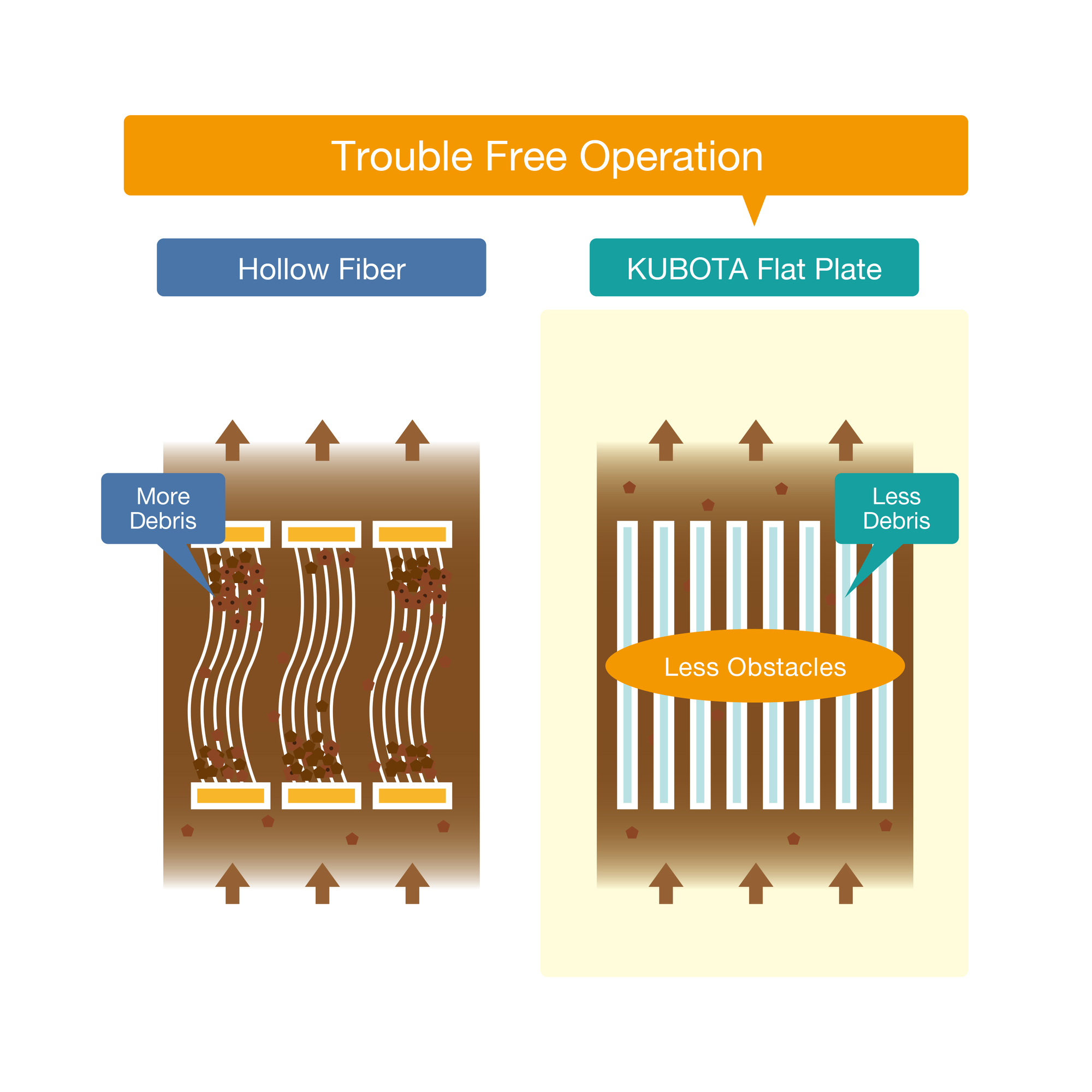

Finally, the robust design of our flat plate membranes provides owners the peace of mind and wory free operation. Our submerged membrane units (SMUs) have fewer restrictions at the top of the membrane compared to hollow fibers. This leads to screening residues such as coarse suspended solids passing between the membranes rather than tangling as they do on hollow fiber systems.

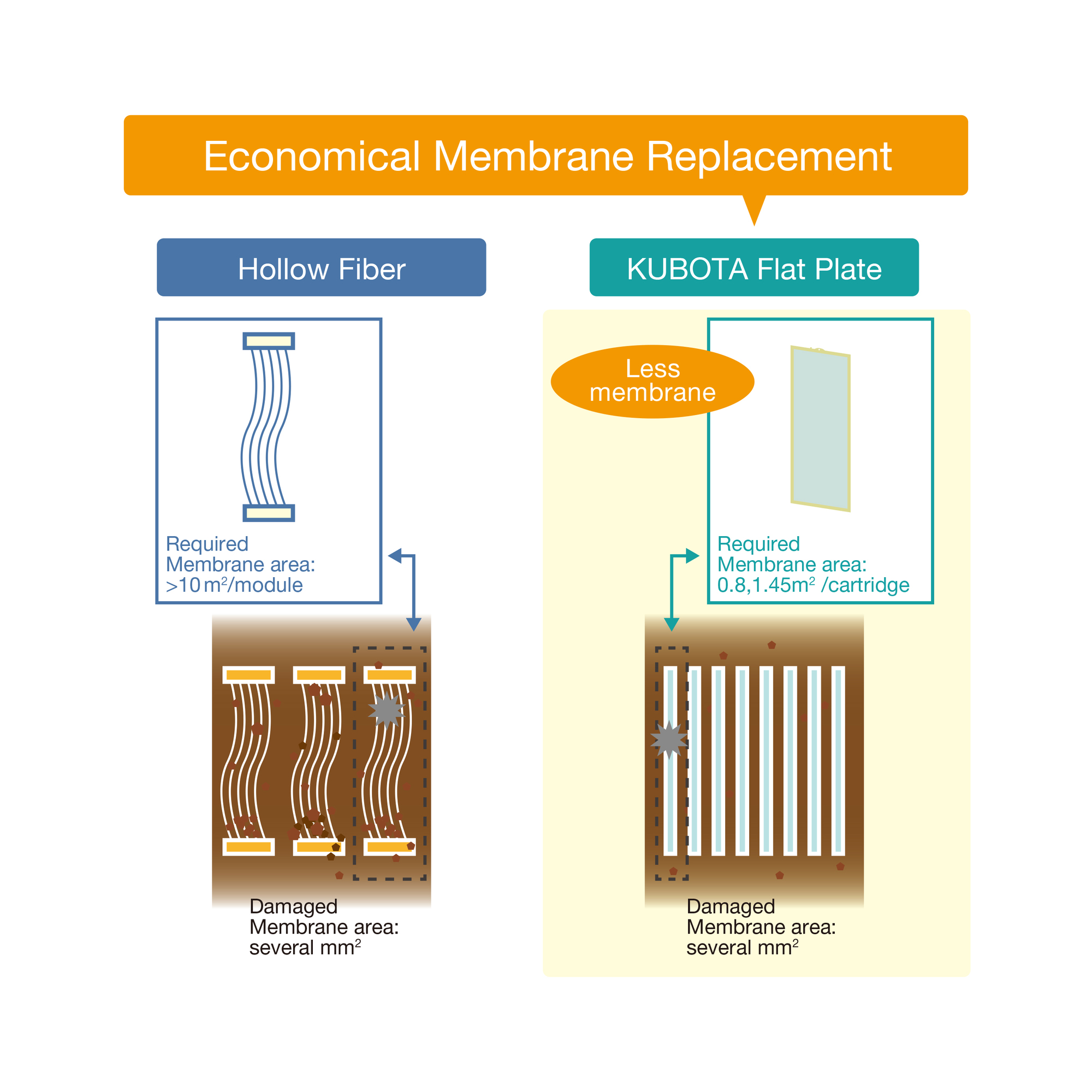

Our SMUs also allow for replacement of individual membranes as opposed to entire racks the way a hollow fiber system does, making membrane replacement more affordable.

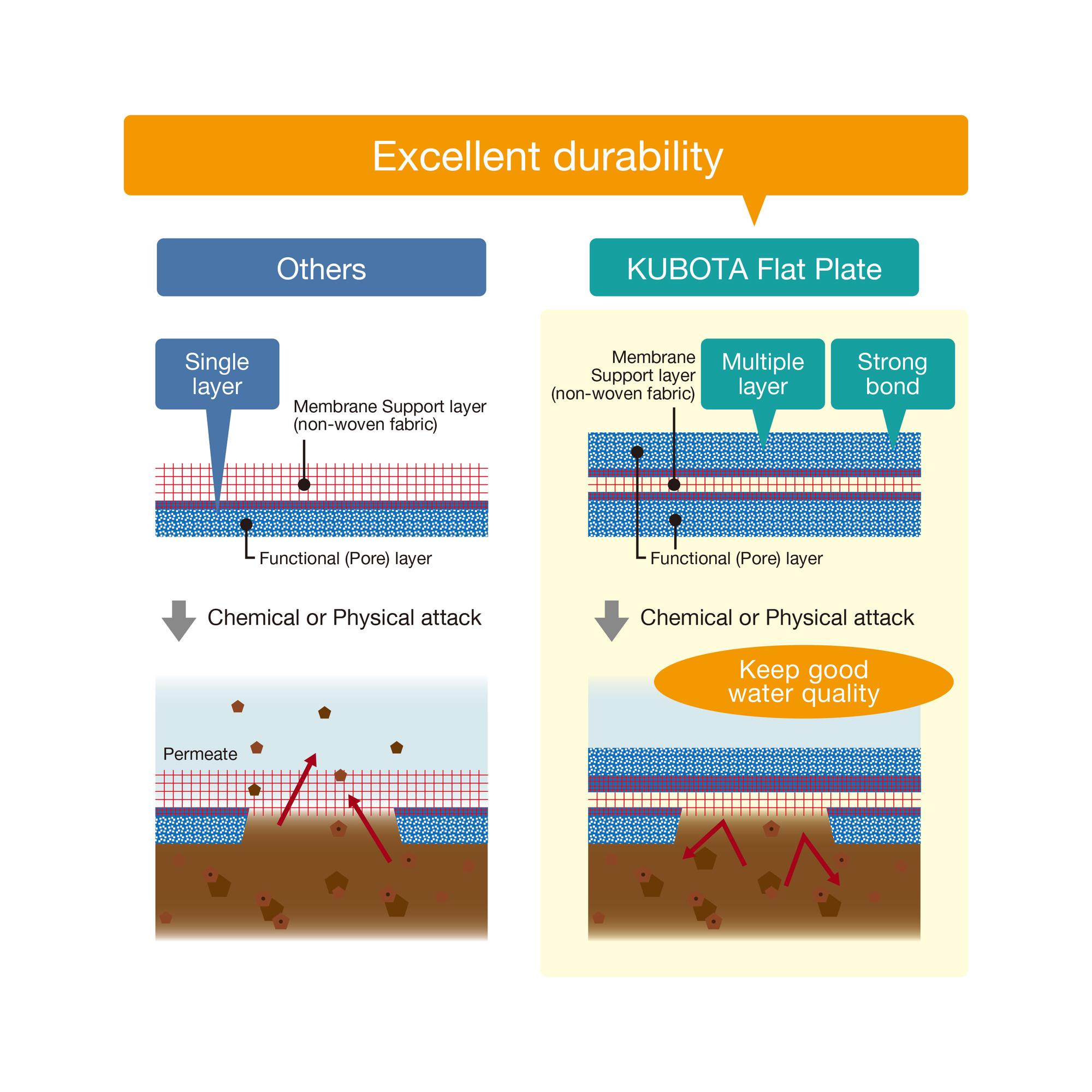

Lastly, our longest in the industry experience has us that our membranes have unparalled durability, allowing us to offer up to 10 years of non-prorated warranty coverage.

For these reasons and more, it’s clear that Kubota’s flat sheet membranes are the best choice for all of your wastewater application needs. Contact us today to learn more.